Choosing a Splitboard: Factory Made vs DIY

With the boom of the backcountry enthusiast, many companies now offer some factory made split options. These can be expensive but there is another option and that is to split a board yourself with a table saw. I've been on both now and feel that I have a good opinion on the matter of whether to go with a factory made splitboard or a DIY splitboard.

Buying just the splitboard itself is the most expensive decision that a snowboarder could make, so it typically takes the longest and most research to make. Splitboards, by themselves, can range in price from $700 upwards to $1200 for the top models. This range could include the hardware that it takes for your bindings but it also might not. With the rest of the gear needed - skins, telescopic poles, hardware (Voile or Karakoram), binding system (whether it's Spark R&D or using old bindings), avalanche gear, avalanche classes (find classes in your area here), GoPro (who cares if you're in the backcountry if you can't post on Facebook?) - you are getting into the $2000 range. So why do it? Well, I will personally say that it's addicting to be out on your own with no crowds and fresh lines all around you. It's the one place where skiing/riding is truely a creative art because you can go where ever you choose. For those who are more analytical and money conscious, you're gear will last more than 2 seasons and for Utahns the same price that would be put into a season pass.

I'll break it down by category and will offer my opinion at the end, but you will obviously ultimately decide which option to go with.

Skinning Uphill

Factory Made - 1 vs DIY - 1

It was difficult to give an advantage either way. Factory made splits skin better in deep powder. They are typically a stiffer board so when put into skin mode, will have stiffer skis. If the skis are too soft, they start to bow as you make your steps in the powder. A soft ski will have less strength and more flex leading to less surface area that you need to be comfortable skinning without feeling like you are near postholing. On the other hand, yes a DIY split will typically be softer and have more flex while skinning, but the board itself will be lighter. It's all about weight in the backcountry and taking off just a few pounds makes a huge difference.

This category is something that you have to decide on your own, if you can sacrifice extra weight for a stiff ski or want a light option but are working harder in deep powder.

Skinning (Traction)

Factory Made - 2 vs DIY - 1

This can be one of the most frustrating things to test. When you split a snowboard on your own, you lose the middle metal edge that a factory would put on the board. Without that metal edge traverses on snow/ice, ice/ice conditions make a quick traverse that would take mere seconds might take a few minutes. Also, not having a metal inside edge is sketchy when you are in a no-fall situation on a face and you can feel it sliding out under you.

|

| Factory made, double metal edged... |

|

| ...versus a DIY with no metal edge but a water proof coating |

Advantage factory made.

Riding Downhill

Factory Made - 2 vs DIY - 2

Riding a factory made splitboard, it is typically going to be stiffer, heavier, and less responsive to a normal snowboard. So when you take a normal put-together snowboard into the backcountry, it's like riding in resort with it. The board performs the way a snowboard would perform. When you do split a board, be aware that the stiffness will decrease a little bit, but honestly I did not see a huge difference. Especially for those who are looking to take a freestyle type board into the backcountry, this is something to consider greatly. Splitboards just don't perform as well because of the sheer weight, making spinning, flips, etc more challenging.

One last point to make here, you have more choice in your camber profile. Companies are beginning to add more board profiles to their splitboards but you might not be able to purchase the exact one you feel comfortable on.

Advantage DIY.

Durability

Factory Made - 3 vs DIY - 2

A snowboard that is designed to be in a resort will last a long life in resort, and a board designed for the backcountry will last a long life in the backcountry. I noticed while skinning on a DIY split that things started to slowly break away. My topsheet was being ripped off from the little ice walls that are created on a skin track after a few days of being there, my edges were slowly getting knicked up, and anything I banged them on while the skis were on my back (mostly rocks) took a serious toll on the board.

Think about how much time you put on a snowboard while in resort. Out west per day, you have at most you can go out for is from 9am - 4pm, a 7 hour period. On average, the chairlift takes about and for the sake of easy math, takes 15 minutes to get to the top of the resort. A single run, might take around 10 minutes to get back to the chair. This gives you about 17 runs ([7x60]/25) that you can hit in a full day. (In reality, most people will put in 4 hours or less.)

When in the backcountry, you are never not on your board, except the rare times you have it on your back for mountaineering purposes. A backcountry splitboard really takes a beating while out there and the last thing you want happening is something busting on your board (or the board itself break) while deep in the backcountry and the only thing that could get you out are your already tired legs postholing home or a helicopter.

Advantage factory made.

Price

Factory Made - 3 vs DIY - 3

Like I said in the beginning, factory made boards are expensive versus a DIY board - you could buy (or cut an old one you never use anymore) and cut it for around $250. The $250 includes the screws and such needed but not the hardware. I am basing this $250 price on what I got at Milosport for my split. I have friends of friends who can probably cut them for cheaper, so know that this is the higher end pricing. So comparing on average, a $900 factory made versus a $500 DIY, the choice is obvious.

Advantage DIY.

Conclusion

Making the decision comes down to what type of rider you are, and ultimately how much you can spend. Personally, I would rather spend the extra money and get a factory made splitboard as my aspirations have taken me deep into the backcountry and I don't want a board to slowly fall apart on me while skinning for days on end. For the rider that is seeking more close-to-home or park style riding, I'd motivate them to split one of their old boards as it is cheaper. Especially for those who are just getting into the sport, it will save money and you might end up not liking it. You can also go with option #3 and just do both. You can never have enough boards in a quiver.

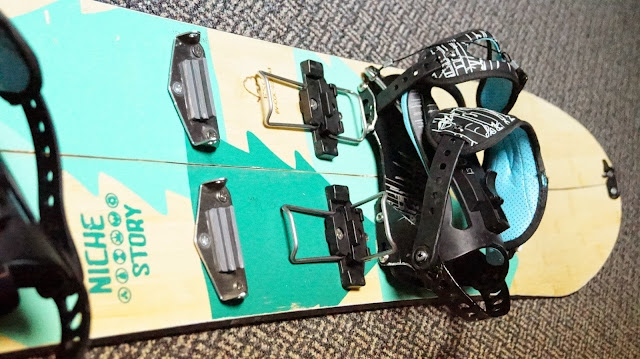

Here's a quick video from my buddy Grant Bowen splitting his Niche Snowboard, in-case you wanted to know what the process entails.

Niche Splitboard Conversion from Matthew Palmer on Vimeo.

3 comments

Interesting, I figured you would have split the board yourself, I can't believe the cost involved with paying someone to do it.

ReplyDeleteIf I had the tools to do it, I'd definitely do it myself. It's tough when you are moving around so much to get any kind of tool box going.

Deleteluckily I don't move around much, and I have a full workshop in my basement.

Delete